This article is part of a blog series introducing the startup teams of the EIT Food Accelerator Network Helsinki 2024 programme.

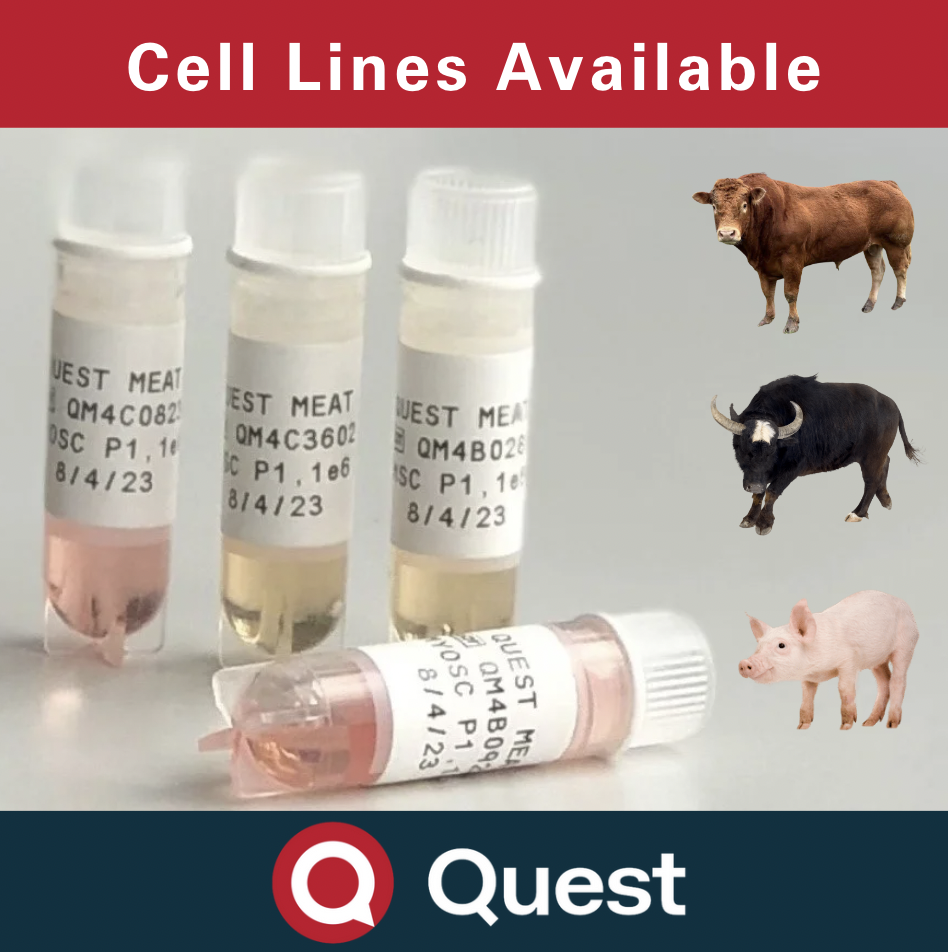

Welcome to Quest, your trusted partner in the cultivated meat production industry. Based in Birmingham, UK, we specialize in creating high-quality cell lines and components that make cultivated meat production affordable and sustainable.

Leveraging our extensive experience in bioprocessing, we are addressing the two major challenges faced by the cultivated meat sector: scale-up and cost-effectiveness. Our strategy involves optimizing the essential raw ingredients needed for cultivated meat, thereby boosting cell yields and reducing production costs.

At Quest, we live by the mantra ‘Junk in, Junk out’. What this means is that to produce highly nutritious, mouth-watering, cultivated meat products, we must begin with top-notch ingredients. Therefore, our current scale-up initiatives focus on high-performing, cultivated meat cell lines and edible microcarriers.

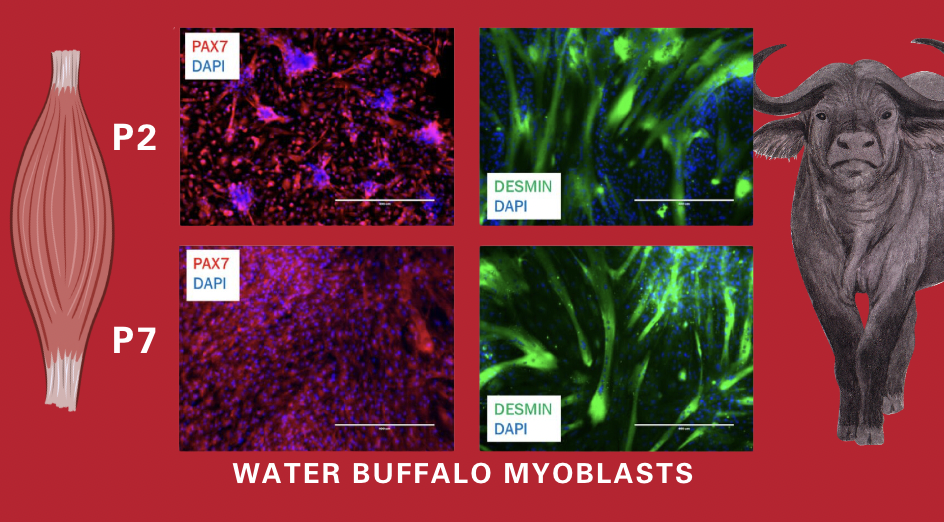

Our cultivated meat cell catalogue boasts an impressive range of different primary cell line offerings. This includes both primary myosatellites (muscle-derived) and adipose (fat) derived primary stem cells from a variety of bovine breeds – British Blue, Limousine, and Aberdeen Angus, as well as pig and water buffalo. Our cells are isolated using a unique, proprietary isolation technique, which results in significantly faster-growing cells compared to those isolated using standard enzymatic methods. Plus, our cells are fully sterility tested, certified free from mycoplasma, bacteria, and viruses, and come with extensive cell expansion data and comprehensive user guides.

We are also thrilled to introduce our edible microcarriers, set to commercially launch in December 2024. These microcarriers, specifically designed for cultivated meat, offer a range of attractive features, including high bead-to-bead transfer, fully sustainable, natural, low-cost, and animal-free material source, and an inherently meaty flavour, aroma, and texture.

Quest’s dedicated team comprises a compact yet highly experienced workforce. Although we are a small group of 7 members, we have over 60 esteemed publications in the field of cultivated meat, bioprocessing, and stem cells, and over 60 years of cumulative hands-on experience in cell sciences, tissue engineering, bioprocessing, and materials science. This wealth of experience and expertise sets us apart and enables us to unlock the commercial potential of cultivated meat.

Being a part of the EIT FAN programme, we are confident that this unique programme will help us speed up our technology within the food sector, and we enthusiastically encourage others in the sustainable food and beverages space to seize this opportunity!

To stay updated with our progress, follow us at LinkedIn or visit our website.

Written by Dr Ella Hodder, Project Manager at Quest.

Learn more about the EIT FAN here.